Our story...until now

We’ve learned a ton since our humble beginnings, in a garage just outside of Owatonna, MN.

That was in 2001, and Sputtering Components founder Dan Crowley was setting out to improve cathodes that applied thin films to architectural glass.

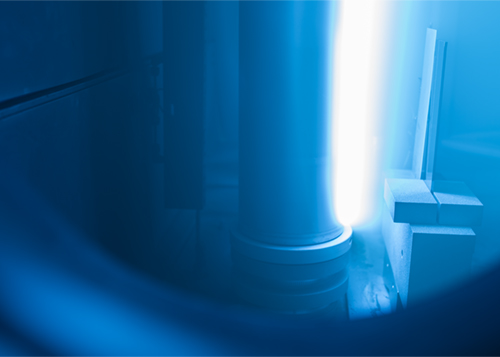

Steadily growing and absorbing what’s important for each industry—and for each project—today we have over 8000 rotary sputtering cathodes (rotary magnetrons) installed around the globe, not only for coating glass but also for making smartphones, display screens, solar panels, automobile parts, decorative hardware, semiconductors and more.

Now a member of the Bühler Group, we are still based in Owatonna but have channel partners around the world.

We are a member of the Society of Vacuum Coaters (SVC), the Association of International Metallizers, Coaters and Laminators (AIMCAL) and are represented on the SVC Foundation (SVCF) board of directors.

2001

Founded in Owatonna, MN by Dan Crowley, who designed, built and shipped product, and Barry Nudelman, owner of a materials company, who supported Crowley's efforts.

2002

Hires its first official employee, Jerry Kelly, who is still with the company today as a Customer Support Coordinator.

2003

Earns its first patent: for its method of target attachment. A year later earns a patent for its method of cathode brushless power transmission.

2006

Moves out of Crowley’s garage and basement and into its own building.

Introduces an external-mount cathode and ships 100 of them for an architectural glass coater soon after.

2008

Relocates to its current factory site.

2011

Ships its 1000th end block.

2012

Expands its representative network in Europe and Asia.

Releases its Swing Cathode™, an end block with a magnet pack that swings in a programmable rotary axis that is independent of the rotating target tube, making it an ideal system for display or 3D part coating.

Starts construction of a 10,000-square-foot addition, which will substantially increase manufacturing capability.

2013

Earns a patent for its magnet bar turnarounds, which increase target utilization.

2015

Releases the Remotely Adjustable Magnet Bar (RAM-Bar™), which allows users to adjust the distance between the magnet pack and the target surface from outside the vacuum chamber during processing to fine tune deposition uniformity in real time.

2016

Ships its 3000th end block.

2018

Becomes a member of the Bühler Group, a Swiss-based company with US headquarters in Plymouth, MN.

2019

Ships its 5000th end block.

2021

Celebrates its 20th anniversary.