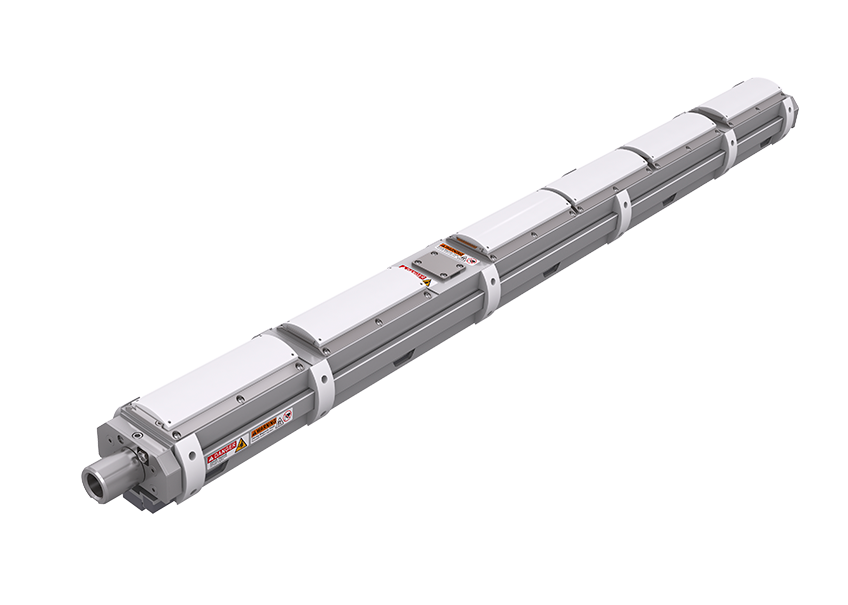

With the Remotely Adjustable Magnet Bar, you can position and fine tune the distance between the magnetics and the target surface from outside the system and during operation to eliminate costly system shutdown.

Compatible with all SCI end blocks and magnet bars for 125 mm ID targets, the RAM-Bar™ allows for up to 4 mm vertical difference between adjustment locations for very fine tuning. It can attain uniformity requirements of less than +/-1%.

Batteries are easily replaceable, standard rechargeable Li-ion packs.

The system has robust industrial communication via Ethernet gateway and fiber optics for control. Multiple magnet bars can be controlled through the coater PLC or using a dedicated computer. The software is easy-to-use and customizable.

The RAM-Bar™ has two methods of operation: precision uniformity adjustment and constant plasma impedance. The constant impedance method can reduce process drift and help stabilize the deposition rate throughout the target lifetime.