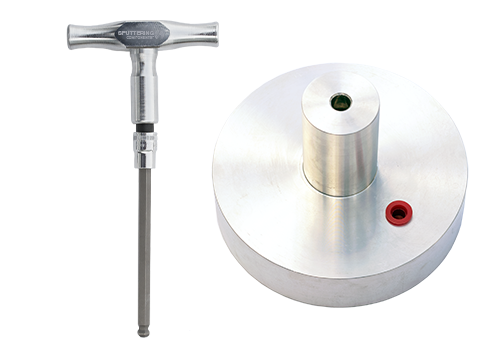

SC Tools

Includes all the tools listed below unless noted

Hold the end block during installation

Align the end block to the outboard assembly during installation; prevents premature part wear

Tighten the drive belt to the optimum amount to prevent slippage and premature wear

Insert and remove the magnet bar during target changes

Align the magnet assembly slot to the key in the end block during target installation

Check for excessive wear on the outboard assembly bushing and the target end cap bushing (go/no-go gauge); for use every vent

Press the bushing into the target end cap

Press the bushing in and out of the outboard assembly

1) Press the vacuum seal assembly into the end block, and 2) press the bearings onto the drive shaft

1) Pull the water seal cartridge out of the end block, and 2) press the water seal cartridge into the end block

Press the vacuum and water seals into the seal housings

1) Push the drive shaft assembly out of the end block, and 2) pull the drive shaft into the end block

Install and remove the target with vertically-oriented cathodes

Holds the seal cartridge when pressing out the seals with an arbor press

Holds the drive shaft when pressing out the bearings with an arbor press