Sputtering Components partners with architectural glass, preservation and decorative glass and auto glass manufacturers around the globe.

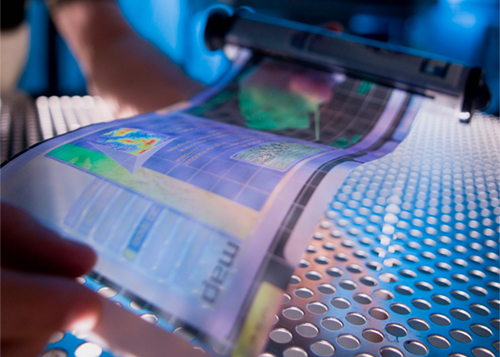

Our rotary magnetrons and complete e-Cathode™ process lid systems are part of large area coaters—including the latest "jumbo" coaters—where reliability is key. Coating campaigns in these types of coaters can last from one week to over one month between vents.

With their high reliability and low cost of ownership, including do-it-yourself-maintenance, Sputtering Components cathodes help keep these coaters running smoothly to reduce the overall cost of production while at the same time improving thin film quality.

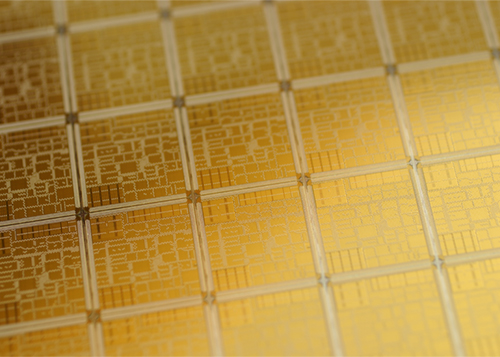

Due to its improved arc rates and higher achievable power densities as compared to sputtering with planar targets, Sputtering Components rotary magnetrons are often used with target materials such as silicon nitride, silicon dioxide, niobium pentoxide and titanium dioxide. For metallic layers, the primary benefit comes from higher material utilization. Overall, cylindrical cathode sputtering reduces the overall cost of production while at the same time improving thin film quality.

With thousands operating around the globe, our SC cathode is the architectural glass industry standard.